Where does Crossdocking have the Best Operational Fit |

| Материал из категории News of logistics (in English) |

| 15.01.2011 23:39 |

|

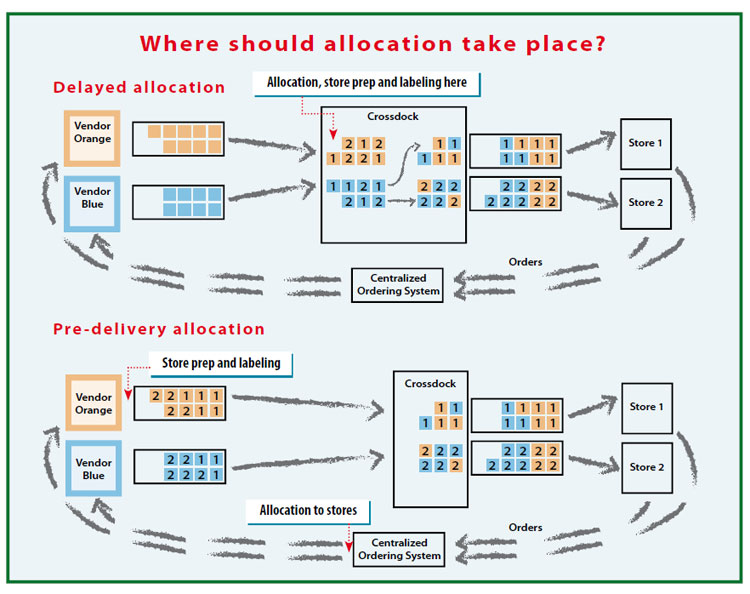

Crossdocking or flow through distribution is a goal of many retailers, but it works better in some scenarios and for some type of goods than others. Last week, we wrote about recent crossdocking research by Dr. Kevin Gue of Auburn University, focusing on the different options for managing retail distribution, such as traditional distribution, direct store delivery and cross docking, and the pros and cons of each approach. This week, we look at Gue's thoughts on where the crossdock model usually has its best fit, and keys to making it a success. So where does crossdocking have the best fit in terms of retail distribution? Gue offers several guidelines: Use crossdocking for products with high, stable demand: If demand is fairly constant, then the inventory serves little purpose, and the product is a good candidate for crossdocking. If demand is highly variable or the cost of a stockout is high, then traditional warehousing is probably the best strategy, Gue says. Use crossdocking for products for which customers are willing to “wait a few days”: This is typical for larger purchase items such as major electronics or appliances. In fact, crossdocking is an essential strategy of Whirlpool's totally redesigned distribution network, enabling the appliance giant to deliver washers and refrigerators to every household in the US in just two days. Gue notes that when a "stockout" in a store does not mean a lost sale, crossdocking can become very attractive. Push distribution systems should crossdock everything that can be sold in stores now: This model is especially associated with heavy discount retailers, such as Ross Dress for Less or TJMaxx, where merchandise is acquired at a discount and everything is pushed to the stores. Customers are used to constantly changing merchandise and inventories. Gue says warehouse club stores such as Costco and Sam's Club take a similar distribution approach for many of their SKUs. When customers have a low expectation that any particular item will be in stock, it is a "perfect situation" for cross docking, Gue says. Gue adds that Ross is very good at merging incoming, crossdocked merchandise with the portion of their inventory that is placed in storage into one outbound truck for a given store, which includes a substantial price ticketing operation. If inventory costs are a concern, delay the allocation of incoming products until they arrive at the crossdock. Otherwise, allocate at the vendor to reduce material handling costs: "Because the lead time in a crossdocking system is longer than in a traditional warehousing system, demand at stores during the lead time could throw off replenishment quantities," Gue notes. "By aggregating orders to a vendor from several stores, and then making a final allocation at the last possible moment, replenishment quantities are as accurate as possible, and inventory costs are reduced." By allocating at the time the Purchase Order is released, retailers can certainly gain efficiencies, using a "Mark for" UCC-128 label in which the store destination of each carton is already known when the vendor ships the goods. But as Gue notes, either demand uncertainty or the actual fill rate from the vendor could make that a riskier strategy, leading to a move to late stage allocation based on the latest demand and inventory data and exact knowledge of what is in the shipment based on the advanced ship notice (ASN).

Source: Kevin Gue/International Commerce Review

For example, Stage Stores, a department store chain that includes under that banner along with Bealls, Peebles and other names, went to a crossdock distribution approach more than a decade ago, but just started to use the late stage allocation model with the past few years, according to Gough Grubbs, EVP of Logistics and Distribution for Stage Stores. Grubbs made his comments on a recent Videocast on The Supply Chain Television Channel. Gue notes that the problem with delayed allocation is that material handling costs in the crossdock can be higher because workers must sort and label incoming products, rather than simply moving them to outbound trailers. "Delayed allocation therefore creates a tradeoff: it reduces inventory costs slightly but increases material handling costs slightly," he says.

Management Challenges The crossdock model is an attractive and powerful option for many retailers, it has its share of challenges, according to Gue. Those include: • Material handling decisions: Poor material handling practices can eat away at much of the potential crossdock savings. What the level of automation should be, especially for crossdocking at the carton level, is a key management decision. Dock congestion can be a big problem, Gue adds. Costco acquired special pallet jacks capable of moving four or even eight pallets at a time to power its crossdock operation, for example. • Cost analysis: Really understanding the potential savings overall and by product and/or vendor is not easy, especially as the inventory savings can be very difficult to estimate in practice. Gue notes Home Depot analyzed vendors one by one to determine which would participate in its new the crossdocking program. Where there wasn't a strong benefit, the vendors products would be kept direct to store or handled through traditional distribution. • Vendor management: Vendors play an essential role in a crossdocking program's success. Understanding each vendor's IT, value-added services, and overall distribution capabilities is essential to avoid many costly and unpleasant surprises down the road. "Crossdocking has been a stunning success for many retailers, but it must not be viewed as the right solution for every firm. Different cost structures, business models, and product mixes may make warehousing or direct-to-stores delivery the right approach," Gue concludes. "For most retailers, the right approach is probably a combination of all three."

Source: Последние похожие материалы:

Более поздние похожие материалы:

|

| Обновлено 24.10.2016 05:56 |

Последние новости на сайте

Пример материалов из категории "Задачи по логистике"

Facebook-страница

Фрагмент из задачи

Группа на Linkedin

(более 4000 участников)

Группы на Facebook

Результаты тестов

| Последние результаты | ||

|---|---|---|

| <-->Стоит ли Вам выбирать профессию менеджера по логистике? | 64.00 % | |

| <->(Лог-М) Тема 10. Складська логістика (10 тест.завдань) | 40.00 % | |

| <->(Log) Test 01. Warehouse and Logistics (10 tests) | 90.00 % | |

| Перейти к тестам |